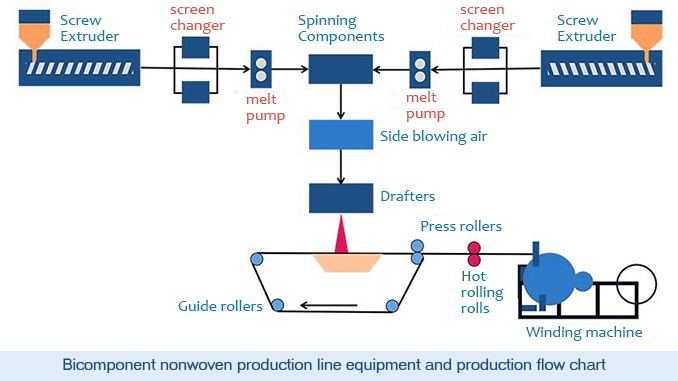

With the continuous progress of science and technology and the improvement of living standards, people have higher and higher requirements for health and hygiene products, thus putting forward higher requirements for the performance of non-woven materials, requiring more soft and comfortable, safe and hygienic, high strength and easy processing. Under such conditions, PE/PP two-component composite spunbond nonwoven has become a new generation of sanitary materials. It is molten polypropylene (PP), polyethylene (PE) heated, extruded from the composite spinning hole into the air by the extruder, the melt flow at a certain speed stretching thin and long, while cooling solidified to form a skin core structure of the filament, the filament through the network, the use of hot-rolled bonding reinforcement to form a non-woven fabric.

Batte offers better solutions for the production principle, common materials, process characteristics, heating temperature, processing pressure and output of bicomponent nonwovens.

Bicomponent composite spunbond nonwoven is the newest international nonwoven production technology. It is a nonwoven fabric made of bicomponent composite fibers instead of single-component fibers by direct spinning into a web, and by hydroentanglement, needling, hot rolling or hot air forming technology. This product combines the characteristics of composite fiber and spunbond nonwoven products to produce.

Common materials: multicomponent polymers

Process characteristics: large amplitude, high output, high filtration precision

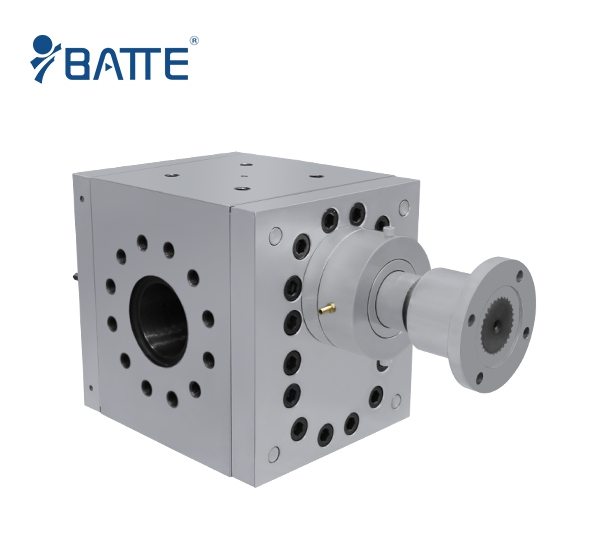

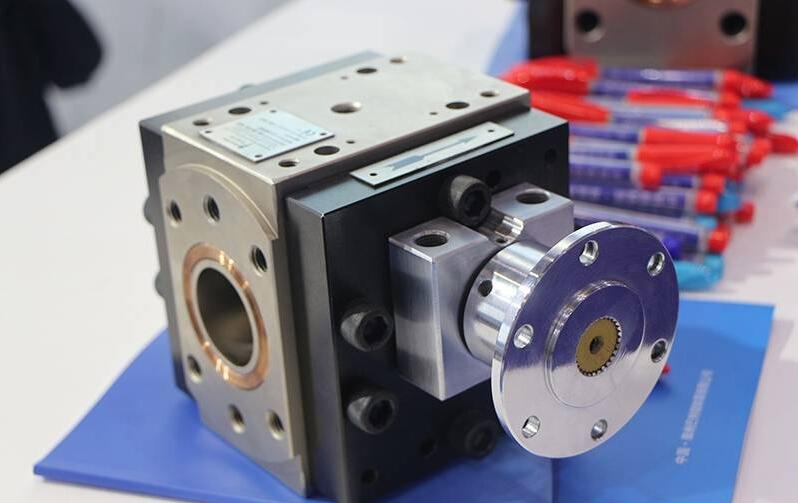

High torque, low shear, high corrosion resistance, very small pressure and flow pulsation, linear flow output, suitable for precision extrusion systems.

Processing temperature: 200-280℃

Processing pressure 3.0-10.0MPa

Output range: 100-1000kg/h

Solution: Non-stop double column screen changer + polymer melt pump

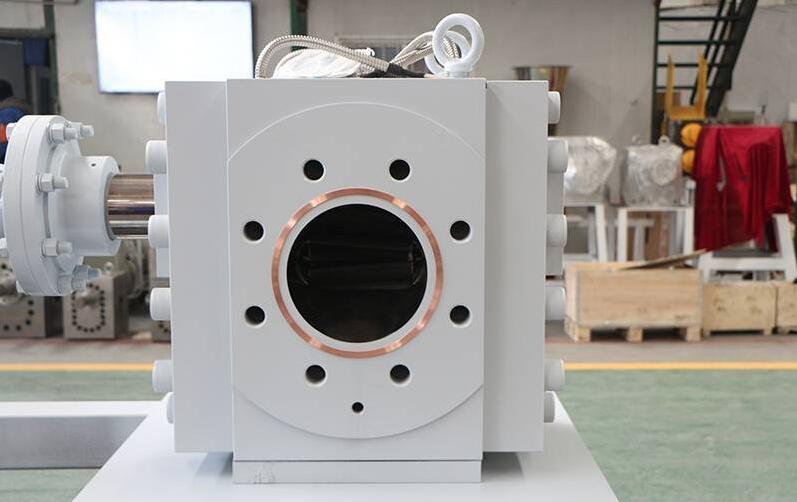

double pillar non stop screen changer

Double column large area screen changer it is built with alloy metal, precision processing, durable; no need to stop when replacing the filter, it can achieve 360 degree filtration, larger filtration area; rigid seal, superior sealing performance; with lead material exhaust structure, more stable and reliable; it is resistant to high pressure, low energy consumption. Filtration area: 300cm²- 6000cm²; Applicable industries: almost all polymer melt filtration; Applicable output: 450-10,000kg/h.

Double column large area screen changer filtration principle: The material flow is from the periphery of the plunger to the inside of the plunger. Under the same plunger diameter, the filtering area of double plunger large area screen changer is more than 4 times of its normal round double plunger screen changer. It adopts the heat medium fluid heating method, which can control the temperature fluctuation of the screen changer body within a very small range.

multicomponent polymers gear metering pump is suitable for conveying melt with relatively high viscosity and no particle-shaped impurities. It has the characteristics of high output pressure, high viscosity of the conveyed medium, high operating temperature, vacuum at the input port, easy adjustment of rotational speed, and large flow range. The material of spunbond nonwoven gear metering pump is made of temperature and wear resistant, corrosion resistant, with sufficient strength and dimensional stability.

Gear metering pump application range

1、Applied to polymerization reaction process, used to transport high viscosity melt.

2、Applied to melt spinning, used as booster pump.

3、Applied to extruder or injection molding machine to improve extrusion efficiency and reduce the load of extruder.

4、Applied to transfer resin and molten resin to make the melt uniform and build pressure to the die head.

The working principle of multicomponent polymers gear metering pump belongs to positive displacement pump, which relies on the change of working volume caused by the mutual meshing of master and driven gears to convey the melt when working. The working volume is composed of the pump body, the gear teeth groove and the bearing sleeve with side plate function. When the gears rotate, the melt enters the teeth grooves of the two gears in the suction chamber, and with the rotation, the melt is brought into the discharge chamber from both sides, and the gears mesh again, so that the melt in the teeth grooves is squeezed out of the discharge chamber and pressed into the outlet pipe. The bearings cannot use the usual lubricating grease to avoid contamination of the melt, and usually use melt self-lubrication.

A complete set of extruder melt pump provided by Zhengzhou Batte includes: motor, reducer, universal coupling, control system and pump body; the structure of the pump body is: main pump body, front cover plate, back cover plate, 2 pairs of D-type bushings, main shaft, driven shaft, seals, etc. info@battemachinery.com