Automatic belt screen changer.pdf

Automatic belt screen changer.pdf

Automatic belt screen changer introduction:

Automatic belt screen changer is designed to be used in every segment of plastics processing including blown & cast film, blow molding, sheet, film extrusion, compounding, etc. Automatic screen changer extrusion is fully automatic screen filters for production lines.

◆ Automatic screen changer consists of screen changer main body, heating or cooling system, electrical control system, etc.

◆ The system control components can automatically governs the filtering time and screen moving speed.

◆ The screen changing is fully automatic and continuous.

◆ The material flowing does not have pulsation, the product shape does not change, and the quality is good during screen changing.

◆ There is no waste or scrap during whole production. The energy consumption is less.

◆ The filter length can be customized between 10 and 20 m. Moreover, the filter can be used continuously for 2 or 6 months.

◆ It is applicable for plastic polymer material, such as PP, PE, ABS, PS, PET, etc.

Automatic screen changer extrusion applications:

◆ Blown & cast film

◆ Sheet

◆ Compounding

◆ Pipe

◆ Tubing

◆ Profile

◆ Multi-layer extrusion

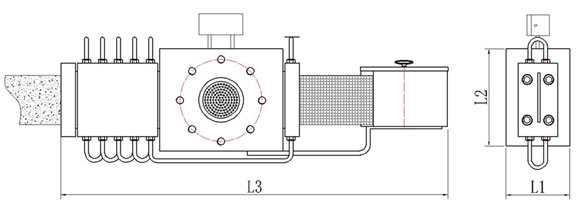

Automatic belt screen changer pictures, drawing, and technical data:

|

Type

|

Output

Kg/h

|

Size (mm)

|

Screen size

|

Heating tube

|

||||

|

L1

|

L2

|

L3

|

Ф(mm)

|

cm2

|

V

|

W

|

||

|

ZB-ACB-50

|

30~85

|

150

|

165

|

540

|

Ф50

|

20

|

230/400

|

5200

|

|

ZB-ACB-70

|

75~200

|

160

|

170

|

560

|

Ф70

|

38

|

230/400

|

5400

|

|

ZB-ACB-90

|

100~290

|

170

|

185

|

580

|

Ф90

|

64

|

230/400

|

5800

|

|

ZB-ACB-100

|

130~350

|

180

|

215

|

605

|

Ф100

|

78

|

230/400

|

6200

|

|

ZB-ACB-120

|

190~500

|

185

|

230

|

645

|

Ф120

|

113

|

230/400

|

6500

|

|

ZB-ACB-150

|

350~800

|

200

|

265

|

700

|

Ф150

|

176

|

230/400

|

7200

|

|

ZB-ACB-180

|

450~1200

|

220

|

305

|

760

|

Ф180

|

254

|

230/400

|

8200

|

|

Type

|

Output

Kg/h

|

Size (mm)

|

||

|

L1

|

L2

|

L3

|

||

|

ZB-ACB-50

|

30~85

|

150

|

165

|

540

|

|

ZB-ACB-70

|

75~200

|

160

|

170

|

560

|

|

ZB-ACB-90

|

100~290

|

170

|

185

|

580

|

|

ZB-ACB-100

|

130~350

|

180

|

215

|

605

|

|

ZB-ACB-120

|

190~500

|

185

|

230

|

645

|

|

ZB-ACB-150

|

350~800

|

200

|

265

|

700

|

|

ZB-ACB-180

|

450~1200

|

220

|

305

|

760

|

Automatic belt screen changer.pdf

Automatic belt screen changer.pdf