Melt gear pumps and screw extruder with the use of extrusion can improve extrusion output and quality, reduce energy consumption, especially in the precision extrusion molding to play the role of other processing means can not be replaced. At present, the materials it can process almost cover most of the polymer materials, such as PE, PC, PP, PVC, PET, polysulfone, polyester, fluoropolymers, thermoplastic elastomers and rubber.

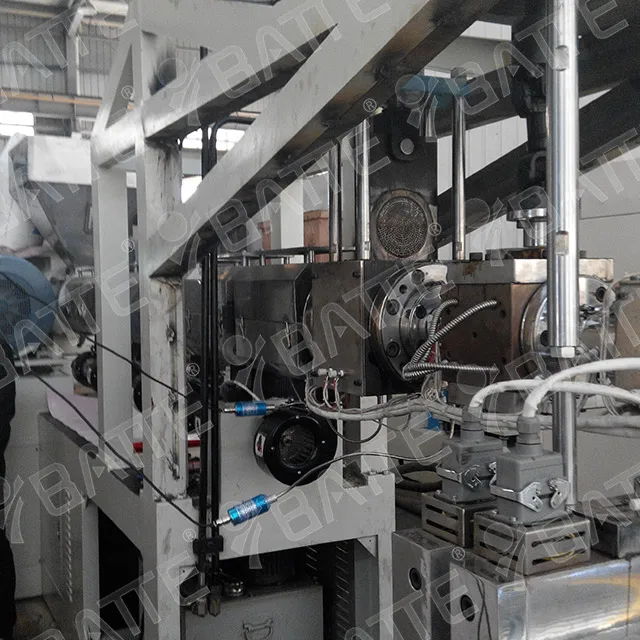

A complete set of melt gear pump includes motor, reducer, coupling and pump head parts. The pump head part is composed of pump casing, front and rear side covers, gear shaft, sliding bearing and shaft seal.

Melt gear pumps are mainly used for melt conveying, pressurizing and metering, and are characterized by compact structure, reliable operation, low energy consumption, high volumetric efficiency, and small shearing effect on the melt. Melt gear pump conveying polymer melt, it should be in the high temperature below 350C, high pressure of 30MPa or so under the conditions of continuous operation; pump material should be temperature, wear and corrosion resistance, should have sufficient strength and dimensional stability.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071