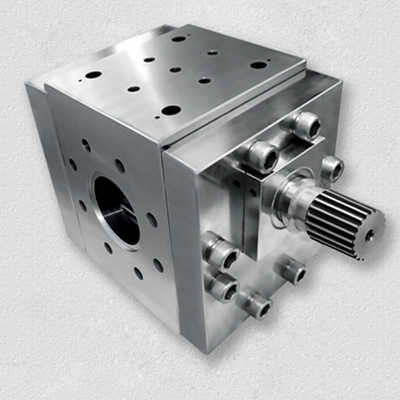

Single screw extruder melt gear pump,Sheet metal equipment dedicated - melt pump (ZB - A)

Single screw extruder melt gear pump

Batte melt pump is mainly used for high temperature and high viscosity of the polymer melt conveying, pressurization and measurement. Its main function is to come from extruder of high temperature melt pressure, voltage stability, maintain the melt flow precise steadily into the extrusion. Today, the melt gear pump has been widely used in chemical fiber, granulation, plastic film, sheet, plate, profiles, pipes, wire and cable, wire drawing, composite extrusion production line, machinable materials almost covers most of the polymer materials, such as: PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymer, polysulfone, polyester, thermoplastic elastomers, rubber and hot glue, etc.

Second, the melt pump application in XPS foaming production line.

Material: PS benzene material instead

1. Φ 135 feed screw parameters: 75 kw motor, temperature range of eight temperature respectively: 172 ℃, 156 ℃, 160 ℃, 160 ℃, 144 ℃, 218 ℃ and 180 ℃

And in 240 ℃ after the network device.

2. Φ 150 extruder screw parameters: 55 kw motor, temperature range of eight temperature respectively: 202 ℃, 162 ℃, 158 ℃, 146 ℃, 110 ℃, 66 ℃ and 75 ℃

93 ℃.

3. The melt pump parameters: 250 cc, 15 kw motor, temperature: 125 ℃ for 15 mpa, inlet pressure outlet pressure is 25 mpa.

4. Mould parameters: do plate specifications 60 * 60 * 2, 2.5, 3, 3.5, 60 * 60 * 60 * 5, 60 * 10 mold temperature 150 ℃

5. Injection gas parameters: the foaming gas CO, injection pressure for 20 to 25 mpa.

The conclusion

1. The viscosity of the melt temperature influence and strength, which affects the melt pump outlet pressure and foaming effect, under the normal extrusion conditions, the melt temperature

The lower, the effect of foam, the better, foaming ideal temperature is 120-150 ℃.

2. Add the melt pump after stabilizes the export of the extrusion pressure fluctuations, made it possible to uniform extrusion, improve the hardness of XPS extruded plate, and can reduce the proportion.