The number of wrapping belt in the packaging industry is very large, the market in Guangdong, China, there are nearly a thousand production lines, basically all with scrap production, impurities and change the net is extremely frequent, and are manually stopped to change the net, resulting in a large number of back to material, waste, easy to form a vicious circle. The strength of the scrap is originally low, and then recycling energy consumption, waste of labor, and then the quality of the product will also be reduced. It is a new multi-station structure with preheating and exhausting mechanism, without any pressure fluctuation when changing the net, which ensures the continuous production and dimensional stability of the baling belt products, realizes no stoppage, no strip, no material leakage, no influence on the production and the size of the belt, and increases production and energy saving, reduces consumption and costs. China Guangdong Foshan, Shenzhen, Zhongshan and Zhejiang, Fujian and Jiangsu regions have many manufacturers have been modified, the user unanimously praise! Products are also exported to India, Philippines, Indonesia, Malaysia, Russia, Turkey, Italy, Mexico, Colombia and other countries.

PP strapping, scientific name polypropylene, is a lighter type of common plastic, PP strapping's main material is polypropylene drawing grade resin, because of its good plasticity, strong fracture tension, bending resistance, light specific gravity, easy to use and other advantages, was processed into a strapping belt, has been widely used in various fields. PP strapping tape appearance: translucent to opaque, transparent film texture. Combustibility: combustible in the flame. After leaving the flame slowly extinguished or continue to burn. Burning flame is yellow at the upper end and blue at the lower end; melting and dripping phenomenon. Can smell the smell of paraffin.

PET strapping is a widely used plastic environmental protection strapping, PET strapping production in China has more than 20 years of history. Since 2002, China's demand for PET strapping has grown at an annual rate of 500%, and is now widely used in wood, paper, steel, aluminum ingots, steel pipes, profiles, glass, building materials, ceramics, electrical appliances, metal products, tobacco, chemical fiber, cotton and other industries. The appearance is transparent, (opaque after adding tackifying additives), and the surface is flat or has an angular pattern.

The main raw material of PET strapping is polyethylene terephthalate (PET for short), with a specific gravity of 1.34. It has strong tensile strength, both steel-like tensile strength and ductility that can resist impact, which can ensure the safety of product transportation.

Material: PP, PET plastic granules

Process characteristics: high output, high temperature, high filtering precision, high viscosity, low pressure fluctuation, high stability and reliability requirements

Heating temperature: 200~280 ℃

Heating pressure: 3.0-10.0 MPa

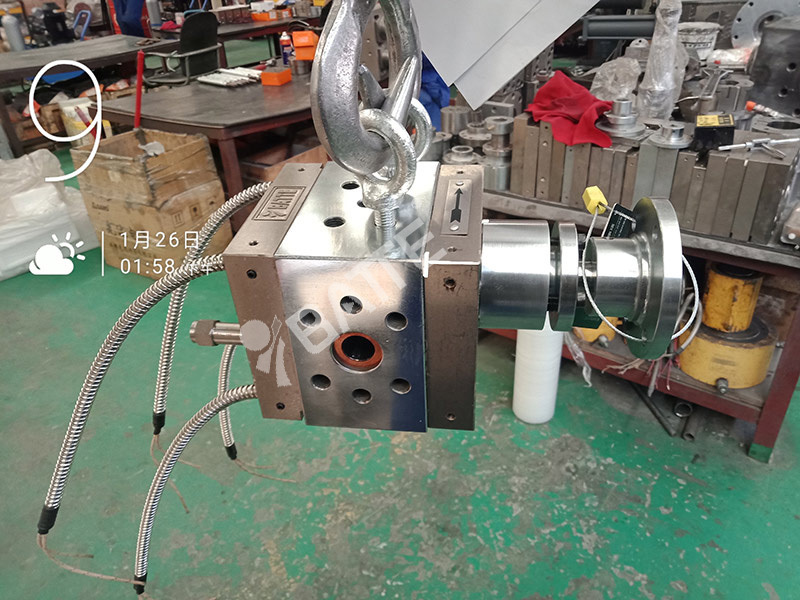

Batte product solution: baling belt melt pump + double column screen changer/ single plate screen changer

Zhengzhou Batte melt pump for baling belt is mainly used for conveying, pressurizing and metering of high temperature and high viscosity polymer melt. According to the process of baling tape production, Zhengzhou Batt melt pump manufacturer has improved the melt pump for baling tape; the pump is installed between the mold and the screen changer and driven by frequency conversion motor.

Zhengzhou Batte melt pump manufacturer has also developed a closed-loop pressure control system (intelligent meter type and PLC type) for this melt pump, using the closed-loop pressure control system can effectively reduce pressure fluctuations, the use of the closed-loop pressure control system and the melt pump can significantly improve product quality and reduce the scrap rate due to dimensional errors.

The pump body of high temperature melt pump is made of CPM tool steel and titanium-tantalum alloy. High temperature melt pump gear material: Hastelloy, special materials and wear-resistant coating. High-temperature melt pump sliding bearing material: titanium-tantalum alloy. High-temperature melt pump can use temperature up to 510℃, and its output pressure can reach 70MPa.

It is a new multi-station structure with preheating and exhausting mechanism, and there is no pressure fluctuation when changing the net, which ensures the continuous production and dimensional stability of baling belt products, realizing no stoppage, no strip, no material leakage, no influence on production and belt size, increasing production and energy saving, reducing consumption and cost. It is a cost-effective and widely used quick non-stop screen changer.

It can quickly switch screens within 1 second, fast screen changing action, small change in material flow, no material leakage, high pressure resistance (peak up to 50MPA), large filtering area, short runner, simple operation, less screen changing waste, easy and fast screen changing, no stopping to change screens. Adopting internal heating, fast heating speed, uniform temperature and low energy consumption.

Packing belt screen changer, two detachable filter stations are designed on the slide plate, when working, one filter station is inside the main body for melt filtration, and the other station is outside the main body for backup (the slide plate is equipped with stainless steel heating rods for heating and heat preservation to ensure the similarity with the production temperature). When the impurities on the filter accumulate to a certain level during the work, it is necessary to change the screen, you can press the button of the operating handle on the hydraulic station to activate the accumulator hydraulic station to change the screen.

Optimized structure design of PET baling belt screen changer realizes screen preheating and lead material row function, completely eliminating the fluctuation of melt pressure and temperature during screen changing; it completely eliminates bubble and impurity defects; optimized screen support plate structure, easy to clean and replace, completely eliminates product defects caused by resin aging black spots; multiple heating methods are designed to ensure the stability of resin pressure and material flow during screen changing.

Batte design baling belt double column screen changer is designed with exhaust system, which can fully exclude the gas entrained in the material and the porous plate to be changed, prevent the formation of gas in the product during the screen changing process, and improve the quality of the product; double column screen changer has a large filtering area, suitable for different materials and different products of extrusion production, with good sealing characteristics, rigid sealing, and long service life.