The simplex systems can be provided with either fixed or removable vessels; a compact preheat station with spare vessel can be provided for locating near the line for quick change out.

They are custom designed to minimize initial pressure drop and maximize filter element life.

Our proprietary sizing program, based on more than 20 years of experience in the field, incorporates your operating data to size each system for maximum performance and optimized flow while maintaining compact dimensions.

The simplex polymer filtration systems provide large-area filtration for the discontinuous production of polymers at the same filtration level and capacity of duplex systems. However the simplex system has the following advantages:

Lower cost

Easier operation

Less space requirements

Minimized pressure drop

Horizontal or vertical design

Discontinuous large area filtration systems

Typical Polymers Handled

ABS

EVA

HDPE, HMWPE

PA 6, PA 66

PB

PE, LDPE, LLDPE

PEEK

PET, PBT

PP

PS, HIPS

Cast film extrusion filters

This table shows nominal flow rate figures for standard 3- and 7-element filters using 61 mm (2.413 in.) OD elements.

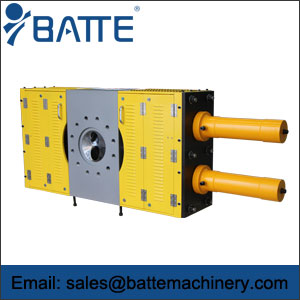

3-element horizontal design

7-element vertical design

Cast film extrusion

Maag also offers special standard designs for cast film extrusion lines.

These compact units are easily added downstream of the extruder and are available in vertical or horizontal configurations. Typical rates are from 225 to 2,050 kg/hr (500 to 4,500 lb/hr).

Construction

Heating: Vessels can be designed for hot oil or electric heating.

Connections: Inlets and outlets can be constructed to accommodate any existing process connections, such as flanged and quick clamp connections.

Codes: manufactures systems to all major design/construction codes and construction quality certificates and inspections.

Filter elements

Manufactures filter elements in a variety of configurations; we can also design to your requirements. Elements we design are optimized for your filter system with respect to flow and filter area.

Integration with pumps

We can provide a fully integrated package including filter, pump, and controls mounted on a common support.