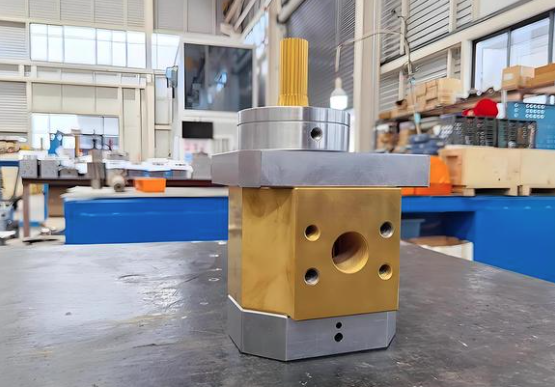

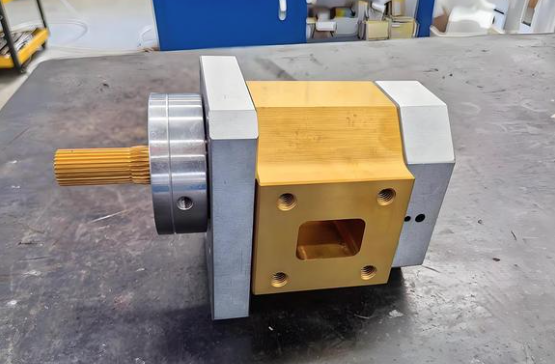

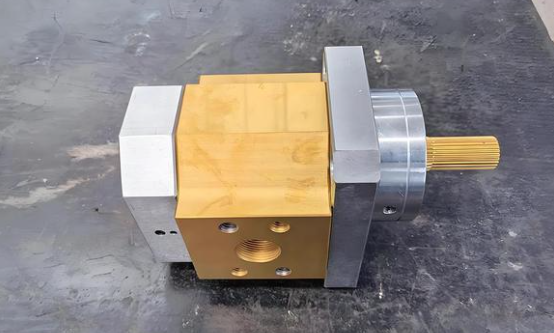

Zhengzhou Batte glue gear metering pump has a unique role and significant features in industrial production, as follows:

Accurate metering: glue gear metering pumps through the precise meshing of gears, to achieve high-precision metering of glue. Whether it is low-viscosity or high-viscosity glue, it can be transported stably according to the set flow rate to ensure that the amount of glue output is the same each time, to meet the requirements of the production process for precise control of the amount of glue, such as in the encapsulation of electronic components in the process of precise control of the amount of glue.

Stable delivery: The rotation of the gears provides stable power, enabling the glue to be delivered continuously and evenly. Even under different working pressures and speeds, the pump can maintain a more stable conveying performance, reducing product quality problems caused by unstable conveying, such as in the packaging industry to ensure that the glue is uniformly applied.

Adapt to a variety of viscosity: the pump can be adapted to different viscosity of the glue, from thin glue to high viscosity paste glue can be effectively transported. Its structural design makes the glue in the conveying process will not affect the conveying effect because of the change of viscosity, expanding its applicability in different application scenarios, such as automobile manufacturing in the use of different types of glue can be dealt with.

Wear-resistant: Because the nature of the glue may be more complex, glue gear metering pumps are usually made of wear-resistant materials, such as special alloys or high-performance plastics, to resist the glue in the conveying process on the pump body and gear wear, to prolong the service life of the pump and reduce equipment maintenance costs.

Good sealing: In order to prevent glue leakage, glue gear metering pumps are equipped with reliable sealing devices. Common sealing methods are mechanical seals and packing seals, etc. These sealing devices can ensure that the glue is transported at the same time, effectively preventing the glue from spilling, to ensure a clean production environment and the safety of the production process.

Easy to control: The glue gear metering pump can be easily integrated with the automation control system, by adjusting the motor speed and other parameters to control the flow of glue and delivery speed. This easy-to-control feature makes it well adapted to the needs of different production processes and realizes the automation and intelligence of the production process.

Email: sale@meltpump.com

WhatsApp: +86 158 38331071