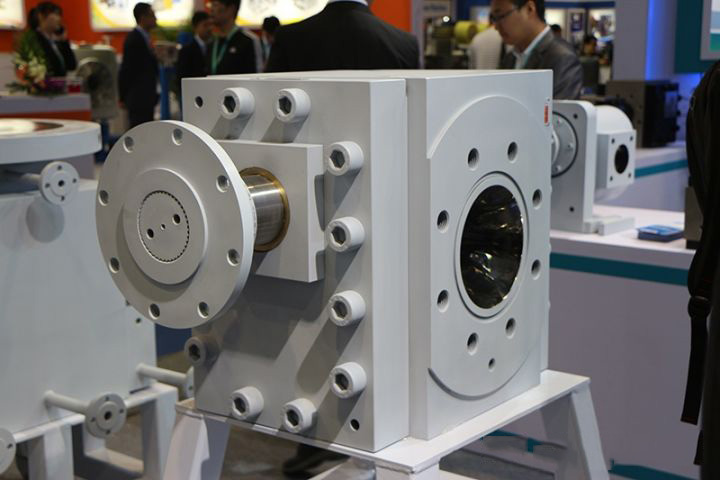

Gear metering pump is a kind of pump equipment widely used in industrial production, which mainly realizes the transportation and metering of fluid through the movement between gears and gears. Compared with the traditional pump equipment, gear metering pump has the advantages of simple structure, stable work, stable flow, accurate measurement and so on. Therefore, it is widely used in chemical, paint, food manufacturing and other industries.

In the production process of composite materials, accurate dosing and composition control have a crucial impact on the quality and performance of the products. Gear metering pumps achieve precise metering of fluids by controlling the rotational speed of the gears and the volume of the pump body. The principle of operation is that the suction and extrusion of fluid is realized through the meshing of gears with each other. One of the gears acts as the driving wheel, while the other gear acts as the driven wheel, and the sealing of the pump body is realized through the gear box between the two gears. When the driving wheel starts to rotate, the fluid is sucked into the pump body, and with the movement of the gears, the fluid is pushed to the outlet and discharged from the pump body. Gear metering pumps have several important applications in the production of composite materials:

1、Accurate measurement of batching: In the batching process of composite materials, the proportion and dosage of raw materials need to be precisely controlled. Gear metering pump through its accurate metering ability, can be realized between different materials to achieve precise proportion control, to ensure the accuracy of product composition.

2、Efficient transportation of ingredients: Gear metering pumps have high flow and pressure capacity, which can quickly and efficiently transport raw materials to the production line of composite materials. In large-scale production, gear metering pumps can improve production efficiency and reduce production costs.

3, stable production process: the working stability of the gear metering pump is very good, to ensure the stability and consistency of the fluid. In the production process of composite materials, fluid stability is critical to the quality of the final product, gear metering pumps can provide a stable flow and pressure output to ensure the consistency and stability of the composite material.

4, automation control: gear metering pumps can be integrated with metering and control systems to realize automation control. By setting appropriate parameters, gear metering pumps can automatically adjust the flow rate and pressure output to realize the automated production of composite materials.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071