Plastic film extrusion process is an important process widely used in packaging, agriculture, construction, aerospace, electronics and other fields. As one of the core equipments of plastic film extrusion process, melt pump plays an important role. This article will introduce the plastic film extrusion process melt pump features, working principle, application and selection of knowledge.

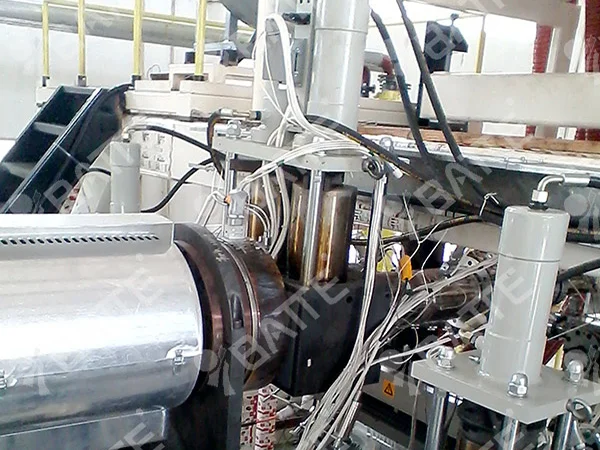

plastic film extrusion melt pump

Melt pump is a high-temperature and high-pressure role, the plastic resin will be melted and pumped to the extruder, through a variety of molds and die molding for different shapes and specifications of plastic products equipment. Melt pump has the following characteristics:

1. the conveying medium is plastic resin, with high viscosity, poor fluidity;

2. the melt pump runs smoothly, with small pressure fluctuation, which can ensure the stable operation of the extruder;

3. the melt pump has a metering function, can accurately control the production volume of the extruder;

4. the melt pump can reduce the power consumption of the extruder, improve production efficiency.

5. melt pump with overload protection function, can avoid equipment damage caused by external factors;

6 melt pump structure is simple, easy maintenance, long service life.

cast film melt pump

Second, the application of melt pump

Melt pumps have a wide range of applications in the plastic film extrusion process. For example, in the production of cast film, the melt pump can melt the plastic resin, transported to the die head of the casting machine, through the die head blowing film to form cast film. In this process, the stable operation of the melt pump can ensure the quality and yield of the cast film.

In addition, the melt pump can also be used in the production of bi-directional stretch film, uni-directional stretch film, multi-layer co-extruded film and so on. In these production, the role of the melt pump is to uniformly transport the plastic resin to a variety of molds and mouth molds, so that it is molded into different specifications and different uses of plastic products. At the same time, the melt pump can also be used in the recycling of waste plastics, waste plastics for high-temperature melting, transported to a variety of molds molded into new plastic products.

thin film polymer extrusion melt pump

In the selection of melt pumps, the following factors need to be considered:

1. the nature of the conveying medium: need to consider the viscosity of the conveying medium, temperature, pressure and other parameters, as well as the chemical nature of the medium whether the melt pump will cause corrosion and other effects.

2. production capacity: according to the production line's output demand, need to choose the appropriate melt pump models and specifications.

3. equipment materials: need to consider whether the material of the equipment can adapt to high temperature, high pressure, corrosion and other harsh environmental requirements.

4. control system: need to consider whether the control system of the equipment has automation, intelligence, remote control and other functions, in order to facilitate the operation and maintenance of the equipment.

thin film melt pump extruder

In short, when choosing melt pumps, it is necessary to make comprehensive consideration according to the actual production demand and equipment parameters, and choose the appropriate models and specifications to ensure the stability of the plastic film extrusion process and production line output requirements.

Email: info@battemachinery.com

WhatsApp: +86 158 38331071