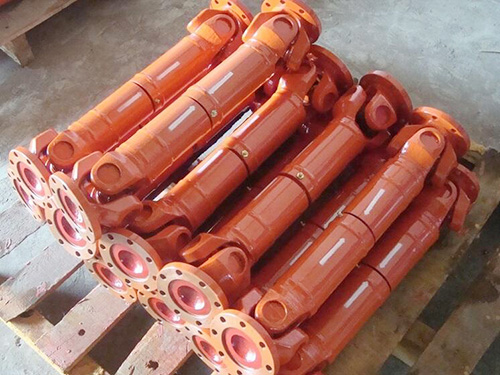

The high temperature melt pump provided by Zhengzhou Batte is connected with the reducer by means of a cross shaft universal coupling, so as to realize the efficient operation of the high temperature melt gear pump. Compared with other couplings, the cross shaft universal coupling has the advantages of compact and reasonable structure, large angle compensation capacity, large bearing capacity and high transmission efficiency. How to install the correct cross shaft universal coupling in the high temperature melt pump, the following specific instructions.

1. Preparations before installation of the cross shaft universal coupling

In order to improve the accuracy of the universal coupling of the high temperature melt pump and reduce the difficulty of installation, some preparatory work needs to be done. First of all, the parts need to be clear and clean, and the surface should be wiped with oil. If you need to install and use it in a short time, you can apply turbine oil or engine oil, which can effectively prevent rust; if you need to store it for a period of time, you also need to apply anti-rust oil. maintenance work.

2. How to operate the cross shaft universal coupling when installing

When installing the universal coupling, first install the two halves of the coupling on the two connected shafts, such as the reducer and the motor, then align the host, and then move and adjust the coupling shaft. The axis of rotation of the host is centered. By measuring the two halves of the coupling, rotating at the same time, the relative position of the radial and axial directions is judged.

3. Precautions for installation of cross shaft universal coupling

a. In order to give full play to the function of the universal coupling, please start the installation within the allowable eccentricity range (the installation error of the universal coupling should not exceed its allowable deviation value, and the deviation value should be less than 3 degrees, so as not to cause additional force , shorten the life of the shaft).

b. When aligning the center, please stick the ruler on the outer periphery of the main body, and use two points that are about 90° apart for inspection. The duration of use of the components is greatly affected by the centroid accuracy.

c. After installing the universal coupling, be sure to add a safety cover. Otherwise, you may be injured by touching the product during operation.

d. The installation error of the universal coupling needs to be strictly controlled, and it is usually required that the installation error should not be greater than half of the allowable compensation amount. Pay attention to check the alignment condition of the connected two shafts after running, and their relative displacement should not be greater than the allowable compensation amount. Minimize the relative displacement as much as possible to effectively extend the service life of the connected machinery or coupling.

e. During installation, the vibration is too large due to the incorrect combination method, which leads to abnormal operation or inaccurate center, and the deflection angle exceeds the load, which will cause damage to the motor, coupling and other parts. action to extend the mechanical use time.

The installation of the cross shaft universal coupling of the high temperature melt pump is not complicated, but it needs to be operated in the correct way. If customers have any questions about the installation process, they can contact us, and professional technical consultants will assist in the installation to ensure the normal operation of the equipment. run. info@battemachinery.com